The laser etching process utilizes a powerful beam of light to alter the surface of various materials. As the laser moves quickly, a permanent mark emerges, showcasing the precision and durability of this method. Numerous industries rely on the laser etching process for producing clear labels. It can be applied to wood, metal, plastic, fabric, leather, stone, or paper, with each material responding uniquely. This versatility makes the laser etching process ideal for a wide range of applications.

Key Takeaways

- Laser etching uses a strong light beam to make lasting marks on many materials. This makes it great for jobs that need accuracy and strength.

- The laser etching process has five main steps: ideation, design, settings, engraving, and completion. These steps help get the same good results each time.

- Safety is very important when using laser etching machines. Always wear safety gear. Keep your work area clean. Make sure there is good airflow.

- There are different types of lasers like fiber, CO2, and UV. Each type works best for certain jobs. Pick the right one for your material and detail needs.

- Laser etching can be used on metals, plastics, ceramics, glass, wood, leather, and composites. Each material needs special care.

- In factories, laser etching helps by making clear marks for tracking and checking quality. This helps lower mistakes.

- Many industries use laser etching, like automotive, electronics, medical, aerospace, jewelry, and packaging. It helps make products safer and easier to track.

- To get the most from laser etching, always test your materials first. Pick machines that fit your project needs.

Table of Contents

Laser Etching Process

Definition

The laser etching process makes marks that last on many materials. It uses a strong light beam that hits the surface. The laser heats the material and changes it. You can see sharp lines, shapes, or words after. Some people think laser etching and laser engraving are the same. Both use lasers, but laser etching only changes the top layer. Laser engraving goes deeper into the material. You pick laser etching if you want quick, neat, and tough marks. It does not take away much material.

Steps

You need to follow steps to finish the laser etching process. Each step helps you get good and steady results. Here is how it usually works in factories:

- Ideation

First, you pick what to mark and choose your material. - Design

Next, you make your picture or words using special software for your laser. - Settings

Then, you put the material in the machine and set power, speed, and focus. - Engraving

After that, you start the machine. The laser etching process marks your design on the surface. - Completion

Last, you take out the finished item and check how it looks.

You do these steps for every project. The laser engraving process is almost the same, but it may need other settings for deeper marks.

Equipment

You must have the right tools for the laser etching process. The machine you pick depends on your material and what you want to do. Here is a table with common machines used in factories:

| Equipment Type | Description |

|---|---|

| CO2 Laser Systems | You use these for marking many types of materials. They have different power levels. |

| Fiber Laser Systems | You pick these for fast marking on metals and plastics. |

| UV Laser Systems | You use these for soft materials and very fine marks. |

| Laser Accessories | You add things like lenses to help the machine work better and fit your setup. |

You might also use machines like fiber laser marking machines, CO2 laser marking machines, diode-pumped laser marking machines, green laser marking machines, and UV laser marking machines. Each one helps with special jobs in the laser etching process or laser engraving.

Tip: Make sure your tools match your material and what you want. This helps you get the best results from the laser etching process.

Safety

Laser etching uses strong machines. You need to follow safety rules. This keeps you and others safe. Here are the most important safety steps:

- Wear Personal Protective Equipment (PPE)

- Always wear safety goggles for laser work. These goggles keep your eyes safe from laser light.

- Put on gloves if you touch hot or sharp things.

- Use ear protection if the machine is loud.

- Keep the Work Area Clean

- Take away things that can burn, like paper or cloth.

- Clean up dust and scraps after each job. Dust can catch fire or hurt the machine.

- Use Proper Ventilation

- Laser etching makes smoke or fumes. You need a good fan or air system.

- Some plastics make toxic gases. Never etch materials you do not know.

- Check the Machine Before Use

- Look at the laser machine for damage or loose parts.

- Make sure safety covers and shields are on.

- Test the emergency stop button before you start.

- Follow Fire Safety Rules

- Keep a fire extinguisher close. Learn how to use it.

- Never leave the machine running alone.

- Get Proper Training

- Learn how to use the laser etching machine first.

- Read the manual and follow the instructions.

Tip: Always pay attention when you use a laser etching machine. If you see smoke or sparks, or hear strange sounds, stop the machine right away.

| Safety Item | Why It Matters | What You Should Do |

|---|---|---|

| Safety Goggles | Keeps your eyes safe from laser light | Wear them every time you use laser |

| Ventilation | Clears away bad fumes and smoke | Use fans or air filters |

| Fire Extinguisher | Puts out small fires fast | Keep it nearby and know how to use |

| Emergency Stop Button | Turns off machine in an emergency | Test it before each use |

Laser machines are very powerful. Good safety habits protect you and your workplace.

Types of Laser Etching

Fiber Laser

Many factories and shops use fiber laser etching. This method uses a fiber optic cable to make a strong light beam. You can mark metals like steel, aluminum, and copper. It works fast and makes accurate marks. Fiber lasers are good for laser engraving because they make sharp and deep lines.

Fiber lasers are very efficient. They turn about 30% of their power into laser light. This means you can do more work using less energy. Fiber lasers can last up to 25,000 hours. This is much longer than other types. You can use them for big jobs without fixing them often.

Here is a table that shows how fiber lasers and CO2 lasers are different:

| Feature | Fiber Laser | CO2 Laser |

|---|---|---|

| Cut Precision | Higher cut precision | Lower cut precision |

| Working Life | 25,000 hours (10x CO2) | Shorter lifespan |

| Energy Efficiency | 30% conversion | 10-15% conversion |

Fiber lasers are best for laser engraving metals. They work fast and make strong marks. Many companies use fiber lasers for part numbers, serial codes, and logos.

Tip: Use fiber laser etching if you want fast, strong, and neat marks on metal.

CO2 Laser

CO2 laser etching uses a tube filled with gas to make a laser beam. You can use this type on wood, glass, leather, paper, and many plastics. CO2 lasers do not work well on bare metals. But they are great for laser engraving non-metal things.

CO2 lasers are fast and make neat marks. You do not need ink or extra stuff to make marks. CO2 lasers can work on many materials. You can switch between them easily. But some materials can change color or get too hot.

Here is a table that shows the good and bad sides of CO2 laser etching for non-metals:

| Advantages | Disadvantages |

|---|---|

| High Precision | Not for Bare Metals |

| Speed | Heat Sensitivity |

| Permanent Marks | Color Dependency |

| No Ink/Consumables | Depth Control |

| Versatility |

You can use CO2 lasers for laser engraving wood signs, glass awards, and leather patches. Many artists and designers like CO2 lasers for creative work.

Note: Always test your material before you start laser engraving with a CO2 laser. Some plastics can make dangerous fumes.

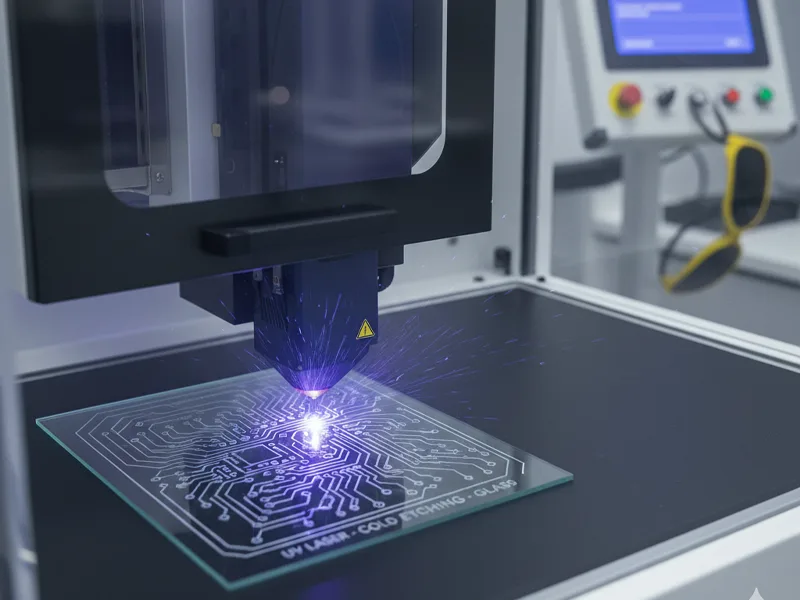

UV Laser

UV laser etching uses ultraviolet light to mark things. This method is good for thin or sensitive materials. UV lasers use cold processing, so they do not heat the material much. You can make clean and sharp marks without damage.

UV lasers are great for laser engraving medical tools, electronics, and fine jewelry. You can mark plastics, glass, and thin films with high detail. The marks are small and clear, which is good for tiny parts.

Here are some special things about UV laser etching:

- It does not make much heat, so it keeps materials safe.

- It is very precise, so you can make tiny marks.

- It makes clean and sharp details without taking away much material.

Use UV lasers when you need very fine detail and do not want to hurt your material. Laser engraving with UV lasers is slower than other types. But you get the best quality.

Tip: Choose UV laser etching for delicate jobs where you need detail and safety.

Comparison

When you choose a laser etching method, you need to know how each type works. Fiber, CO2, and UV lasers have different strengths. You can use each one for special jobs. Let’s look at how they compare.

| Feature | Fiber Laser | CO2 Laser | UV Laser |

|---|---|---|---|

| Best For | Metals, Plastics | Non-metals, Organics | Sensitive Materials |

| Speed | Fast | Medium | Slow |

| Detail Level | High | Medium | Very High |

| Heat Effect | Medium | High | Low |

| Lifespan | Long | Medium | Medium |

| Cost | Higher | Lower | Higher |

| Maintenance | Low | Medium | Medium |

Fiber Laser

You use fiber lasers when you want to mark metals. These lasers work fast and make strong marks. You get sharp lines and deep cuts. Fiber lasers last a long time. You do not need to fix them often. You pay more for fiber lasers, but you save money over time.

CO2 Laser

CO2 lasers work best on wood, glass, leather, and some plastics. You can use them for art, signs, and packaging. These lasers make neat marks but do not work well on bare metals. CO2 lasers cost less than fiber lasers. You need to check the material before you start. Some plastics make bad fumes.

UV Laser

UV lasers help you mark thin or sensitive materials. You use them for medical tools, electronics, and jewelry. These lasers make very fine details. UV lasers do not heat the material much. You get clean marks without damage. UV lasers cost more and work slower than other types.

Tip: Always test your material before you pick a laser type. Some materials react in strange ways.

How to Choose the Right Laser

You need to think about your project. Ask yourself these questions:

- What material do you want to mark?

- Do you need fast work or fine detail?

- How much can you spend?

- Do you need marks that last a long time?

If you want to mark metal parts quickly, pick a fiber laser. If you work with wood or glass, use a CO2 laser. If you need tiny marks on sensitive items, choose a UV laser.

Note: The right laser helps you get the best results. You save time and money when you match the laser to your job.

You can see that each laser type has a special use. You need to know your needs before you start. This helps you make smart choices and get good results every time.

Materials

Laser etching can mark many different materials. You can use it on metals, plastics, and ceramics. Each group has special traits and needs careful work.

Metals

Laser etching is used a lot for metals. The marks are strong and easy to see. People use it for machine parts, electronics, and art. The table shows some metals and how they are used:

| Metal | Typical Applications |

|---|---|

| Stainless Steel | Industrial applications, medical devices, kitchenware |

| Aluminum | Electronics, promotional items, personalized gifts |

| Brass | Decorative applications, plaques, awards, signage |

| Copper | Artistic applications, electrical components |

| Titanium | Aerospace, medical, automotive industries |

Steel

Factories often pick steel for laser etching. Stainless steel is tough and does not rust. You can mark tools, machine parts, and medical gear. The marks stay clear after cleaning or heavy use. Steel shows sharp lines and high contrast.

Aluminum

Aluminum is light and easy to shape. You see it in electronics, car parts, and gifts. Laser etching makes bright, lasting marks. You can add logos, numbers, or designs. Aluminum does not rust, so marks last a long time.

Copper

Copper is soft and carries electricity well. You use it for wires, circuit boards, and art. Laser etching lets you make small details on copper. Artists and engineers like copper for its color and shine.

Plastics

You can mark many plastics with laser etching. Some plastics work better than others. Always check if your plastic is safe for lasers.

ABS

ABS is a common plastic in toys, car parts, and electronics. Laser etching gives smooth, dark marks. Be careful because ABS can make harmful gases. Make sure your area has good airflow.

Polycarbonate

Polycarbonate is strong and clear. You find it in safety glasses, phone cases, and covers. Laser etching makes neat, white marks. Polycarbonate does not crack easily, so marks stay strong.

Ceramics

Ceramics are hard and can take heat. You see them in tiles, medical tools, and electronics. Laser etching changes the surface but does not break it. You get fine marks for labels or art.

- Laser etching can change the color of ceramics.

- You see tiny laser dots but no cracks or breaks.

- The ceramic stays strong after marking.

| Aspect | Findings |

|---|---|

| Microstructure | Laser etching makes crystals smaller and less dense. |

| Optical Properties | You notice big changes in how light goes through the material. |

| Mechanical Strength | New chemical and optical features may show up, but strength stays the same. |

Tip: Always test your materials before you start. Some plastics and ceramics react in different ways to laser etching. You get the best results when you match your machine to the material.

Glass

You can use laser etching to mark glass with clear and permanent designs. Glass is a popular choice for awards, drinkware, windows, and art pieces. When you use a laser on glass, the beam heats the surface quickly. This heat causes tiny cracks that form a frosted look. You can create logos, text, or patterns that stand out.

Laser etching works best on flat glass. Curved surfaces need special setups. You should clean the glass before you start. Any dust or oil can affect the final result. If you want to avoid deep cracks, use lower power settings. This helps you get smooth and even marks.

Here are some common uses for laser etching on glass:

- Personalizing trophies and awards

- Adding names to glasses or bottles

- Decorating mirrors and windows

Tip: Always test a small area first. Different types of glass react in different ways to the laser.

| Glass Type | Common Use | Etching Result |

|---|---|---|

| Soda-lime Glass | Drinkware, windows | Frosted, white mark |

| Borosilicate | Lab glass, cookware | Fine, smooth mark |

| Crystal | Awards, art pieces | Bright, sharp mark |

Wood

Laser etching on wood gives you a natural and warm look. You can use many types of wood, such as maple, cherry, or bamboo. The laser burns the surface, leaving dark lines or patterns. You can make signs, gifts, or art with this method.

Different woods react in unique ways. Soft woods burn faster and give darker marks. Hard woods need more power but show fine details. You should always check the grain and finish of your wood. Some finishes can change color or smoke when heated.

You can use laser etching on wood for:

- Custom signs and plaques

- Personalized gifts like cutting boards

- Decorative wall art

Note: Use a fan or air filter. Burning wood can make smoke and smell.

Leather

Laser etching lets you add detailed designs to leather. You can mark wallets, belts, shoes, or bags. The laser removes the top layer of leather, making a dark and smooth mark. You can create logos, names, or patterns that last a long time.

Natural leather works best for laser etching. Synthetic leather may melt or give off fumes. Always check the type of leather before you start. You should also test a small spot to see how the material reacts.

Common uses for laser etching on leather include:

- Branding company logos on products

- Personalizing gifts with names or initials

- Creating custom patches for jackets or hats

Laser etching works well on many materials. You can choose glass, wood, or leather for your next project. Each material gives you a unique look and feel.

Composites

You might use composites if you want parts that are strong and light. Composites are made by mixing two or more different materials together. You often find them in airplanes, cars, and sports gear. Some examples are carbon fiber, fiberglass, and reinforced plastics. Each kind has its own good points, like being tough or not getting damaged by heat.

Laser etching works on many kinds of composites. You can use it to put serial numbers, logos, or safety notes on parts. The laser only changes the top layer, so the inside stays strong. The marks are clear and last a long time. They do not rub off easily. This helps you keep track of parts and make sure they are good quality.

When you use laser etching on composites, you need to think about what is inside. Some have layers of plastic and fiber. The laser might work differently on each layer. For example, carbon fiber takes in the laser well, so you get dark and sharp marks. Fiberglass might need more power to look the same. Always test a small spot first to see what happens.

Here are some ways people use laser etching on composites:

- Marking airplane parts so you can track them

- Putting serial numbers on car panels

- Labeling sports gear like helmets or bike frames

- Adding safety warnings on machine covers

| Composite Type | Common Use | Laser Etching Result |

|---|---|---|

| Carbon Fiber | Aerospace, bikes, cars | Dark, high-contrast marks |

| Fiberglass | Boats, panels, helmets | Light, visible marks |

| Reinforced Plastics | Electronics, tools | Clear, durable marks |

Tip: Always use good airflow when you etch composites. Some materials can make smoke or fumes when the laser heats them.

You should also check how thick your composite is. Thin parts can get hot fast, so use less power. Thick parts can take more energy, but you still need to be careful not to burn or melt them. If you want the best marks, match your laser settings to the type of composite.

Laser etching is a quick and easy way to mark composites. You can make sure every part has the right label. This helps you follow the rules and keep your products safe.

Industry Applications

Manufacturing

Laser etching has changed how factories work. You can use it for many jobs. It helps you make things faster. There are fewer mistakes. Factories use laser engraving for clear marks that last.

Marking

Laser etching is used for marking products. It makes sharp barcodes and serial numbers. You also get strong labels. These marks help you sort parts. They help you make fewer errors. You can track items from start to finish. Laser engraving is good for signs and small parts.

Here is a table with common uses and their benefits:

| Application | Benefits |

|---|---|

| Barcodes and Serial Numbers | Helps you organize and make fewer mistakes. |

| Mass Production | Good for fast work and tight deadlines. |

| Precision Etching | Makes detailed marks for small products. |

| Versatility | Works on many metals and thicknesses. |

You can mark metals and plastics. This makes laser engraving a top choice for product marking in many industries.

Surface Texturing

Laser etching can change how surfaces feel and look. You can add textures for better grip. You can make patterns on tools and machine parts. It also works for consumer goods. Texturing makes products look nice and feel better. You see it in medical devices and electronics too.

Cleaning

Laser cleaning uses the same technology as laser engraving. You can remove rust, paint, or dirt. You do not need chemicals. This way is safe and quick. You keep your workspace clean. You also protect the environment. Laser cleaning works on metals, ceramics, and composites.

Drilling

Laser drilling makes tiny holes in materials. You use it for electronics and medical devices. It also works for aerospace parts. The laser gives you good control. You can drill very small and accurate holes. This process is best for thin materials.

Cutting

Laser cutting shapes materials with high precision. You use it for metals, plastics, and wood. The laser makes clean edges and sharp corners. You can create complex designs for signs and machine parts. Laser engraving and cutting often go together in factories.

Welding

Laser welding joins materials together. The laser melts the edges and fuses them. This process is quick and strong. You see laser welding in cars, planes, and electronics. The welds are clean and need little finishing.

Wire Stripping

Laser wire stripping takes insulation off wires. You use it in electronics and cars. The laser does not hurt the wire. You get clean and accurate results. This helps you get wires ready for assembly or repair.

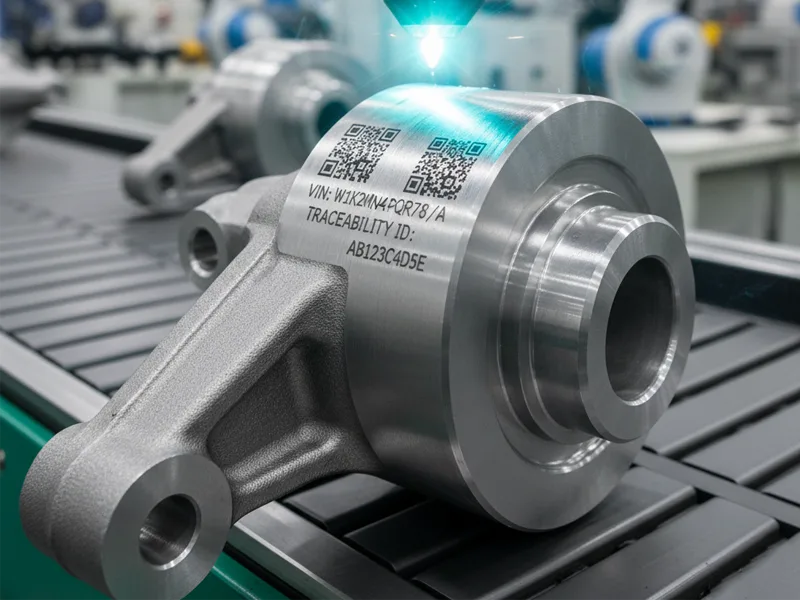

Automotive

Laser etching is important in making cars. You use it for marking parts and tracking them. It helps you keep cars safe and high quality.

Interior Engraving

Laser engraving adds details to car interiors. You can mark buttons and dashboards. You can also mark trim pieces. The marks are clear and last long. You can make custom designs or add logos. Laser engraving gives a professional look.

VIN Marking

VIN marking is key for tracking cars. Laser etching puts permanent VINs on frames and parts. These marks help you track cars and stop theft. The marks do not fade or wear away.

Part Traceability

Laser etching helps you track every car part. You mark each part with a special code. This makes it easy to know where a part came from. You can manage recalls and fix problems fast. Laser engraving works with digital systems for tracking.

Here are ways laser etching helps with tracking and quality in cars:

- You get permanent codes for each part. This helps you track and manage data.

- You collect info like dates and batch numbers. This helps you recall products and spot fake parts.

- You use digital systems to read part codes. This helps you make better choices and control processes.

- You mark each part with an ID code. This helps you track who made it and when.

- You make fewer mistakes with clear marks. This helps you fix problems.

- You find bad parts quickly. This helps you solve issues and work better.

Laser engraving in cars helps you keep parts safe and organized. You can trust the marks to last and stay easy to read.

Electronics

Laser etching is needed in electronics factories. You use it for marking circuit boards and labeling parts. You also use it for marking wires. These jobs help you keep products reliable and easy to track.

PCB Marking

Laser etching marks PCBs with barcodes and numbers. The marks are exact and do not hurt the board. You can track each board during making and testing. Laser engraving helps you meet quality rules.

Laser etching makes detailed marks on small spaces. You can add codes for tracking and quality checks. The process is accurate and does not harm other parts. This helps you work faster and better in electronics.

Component Labeling

Laser engraving labels electronic parts. You can mark resistors and chips with numbers or logos. The marks help you know each part. You can track parts from building to finished product.

Wire and Cable

Laser etching marks wires and cables. You can add numbers or codes for easy sorting. The marks do not rub off or fade. You can organize wires in devices and cars. Laser engraving makes your work quicker and more exact.

You see laser etching in many electronics jobs. It helps you keep products sorted and meet industry rules.

Medical

Laser etching plays a big role in the medical field. You see it on devices, tools, and implants. The marks help you keep track of items and make sure they are safe to use. Laser engraving gives you clear and permanent marks that do not wear off.

Device Marking

You need to mark medical devices with codes, numbers, or logos. Laser engraving lets you do this with high accuracy. The marks stay readable after cleaning or sterilizing. Hospitals use these marks to track devices and follow safety rules.

- You can add serial numbers to monitors and pumps.

- You can mark company logos on surgical trays.

- You can use barcodes for inventory control.

Tip: Laser engraving helps you meet strict medical standards. You can trust the marks to last through many uses.

Surgical Instruments

Surgical instruments need clear identification. You use laser engraving to put numbers, batch codes, or symbols on tools like scissors, forceps, and scalpels. The marks do not fade after washing or sterilizing. You can sort instruments quickly and avoid mix-ups.

| Instrument | Marking Purpose | Benefit |

|---|---|---|

| Scalpels | Serial number | Easy tracking |

| Forceps | Batch code | Quality control |

| Retractors | Hospital logo | Ownership identification |

Laser engraving makes your work safer and more organized. You can find the right tool fast and keep records for each one.

Implants

Implants need special marks for safety and tracking. You use laser engraving to add codes, dates, or patient info to items like joint replacements, dental implants, or pacemakers. The marks do not harm the implant or the patient. You can check the implant history if needed.

- You can mark titanium hip joints with serial numbers.

- You can add batch codes to dental screws.

- You can put dates on pacemaker cases.

Laser engraving helps you follow medical rules and keep patients safe. The marks stay clear for many years.

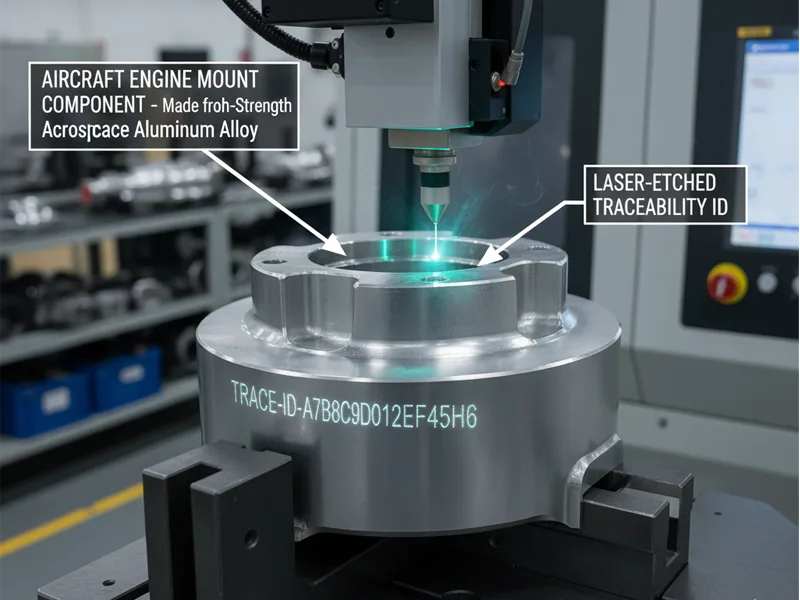

Aerospace

Laser etching helps you in the aerospace industry. You use it to mark parts, add safety notes, and keep up with maintenance. Laser engraving gives you marks that last in tough conditions.

Component ID

You need to track every part in an airplane or spacecraft. Laser engraving lets you add serial numbers, barcodes, or QR codes to metal and composite parts. The marks help you follow each part from building to flying.

| Component | Mark Type | Use Case |

|---|---|---|

| Engine parts | Serial number | Maintenance tracking |

| Panels | QR code | Assembly verification |

| Fasteners | Batch code | Quality assurance |

Laser engraving makes it easy for you to find and check parts. You can avoid mistakes and keep records for safety.

Safety Marking

Safety is very important in aerospace. You use laser engraving to add warning signs, instructions, or emergency info to panels, doors, and controls. The marks do not fade in heat, cold, or vibration.

- You can mark emergency exits with clear signs.

- You can add warnings to fuel tanks.

- You can put instructions on control panels.

Note: Laser engraving helps you meet strict safety rules. You can trust the marks to stay readable in any condition.

Maintenance

Maintenance teams use laser engraving to keep track of repairs and checks. You can mark dates, technician names, or inspection codes on parts. The marks help you know when a part was last checked or fixed.

- You can add inspection dates to landing gear.

- You can mark technician IDs on engine covers.

- You can put service codes on hydraulic lines.

Laser engraving helps you keep planes safe and ready to fly. You can find problems fast and keep good records.

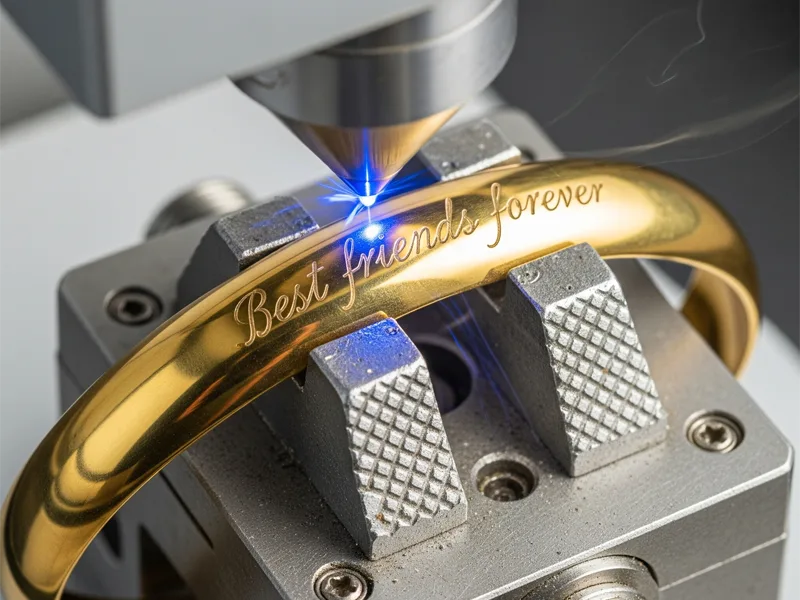

Jewelry

Laser etching brings new options to jewelry making. You use it for custom designs, branding, and stopping fake products. Laser engraving gives you fine detail and lasting marks.

Custom Engraving

You can offer custom jewelry with laser engraving. You add names, dates, or messages to rings, bracelets, or pendants. The marks are neat and do not wear off. Customers like personal touches on gifts.

| Jewelry Type | Custom Marking | Example |

|---|---|---|

| Rings | Names, dates | “John & Mary 2024” |

| Bracelets | Messages | “Best Friends Forever” |

| Pendants | Symbols | Heart, star, initials |

Laser engraving lets you create unique pieces for every customer. You can make gifts special and memorable.

Branding

Jewelry brands use laser engraving to add logos or trademarks. You can mark the inside of rings or the back of pendants. The marks show your brand and help customers know your products.

- You can add your logo to gold chains.

- You can mark silver earrings with your trademark.

- You can put your brand name on watch cases.

Laser engraving helps you build trust and stand out in the market.

Anti-Counterfeiting

Fake jewelry is a big problem. You use laser engraving to add hidden codes or micro-marks that are hard to copy. These marks help you prove your products are real. You can check the code with a special tool.

- You can add tiny serial numbers to diamonds.

- You can mark gold bars with secret symbols.

- You can put QR codes on luxury watches.

Tip: Laser engraving protects your brand and helps customers buy with confidence.

Packaging

Laser etching helps you make packaging smarter and safer. You can add important information to boxes, bottles, and wrappers. This process gives you clear marks that last. You see laser etching in food, drinks, cosmetics, and many other products.

Date Coding

You need to show when a product was made or when it expires. Laser etching lets you add date codes to packaging. These marks do not rub off or fade. You can trust them to stay readable.

- You mark milk cartons with “Best By” dates.

- You add production dates to snack bags.

- You put expiration dates on medicine bottles.

Laser etching works fast. You can mark thousands of packages every hour. You do not need ink or stickers. This saves you money and time.

Tip: Use laser etching for date coding if you want marks that last through shipping and storage.

Batch Numbers

Batch numbers help you track groups of products. You use them to find out where and when something was made. Laser etching puts batch numbers on packaging with high accuracy.

- You add batch codes to cans and jars.

- You mark boxes with lot numbers for easy sorting.

- You use batch numbers to manage recalls.

Laser etching makes each batch easy to trace. You can find problems fast and fix them. This keeps your customers safe and your business strong.

| Packaging Type | Example Batch Mark | Benefit |

|---|---|---|

| Soda Can | “Batch 20240601” | Quick recall |

| Cookie Box | “Lot A123” | Easy tracking |

| Medicine Pack | “BN 7890” | Safety and compliance |

Barcodes

Barcodes help you scan and track products. Laser etching puts barcodes on packaging with sharp lines. You can scan these codes at stores, warehouses, and shipping centers.

- You add barcodes to food wrappers for checkout.

- You mark shipping boxes for inventory control.

- You use barcodes to sort products in factories.

Laser etching makes barcodes that do not fade or smear. You get fast and accurate scans every time.

Note: Laser-etched barcodes help you move products quickly and avoid mistakes.

Pharmaceuticals

Laser etching is very important in the pharmaceutical industry. You use it to follow strict rules and keep products safe. You can mark pills, bottles, and packages with clear codes and numbers.

Compliance

You must follow laws and rules in pharmaceuticals. Laser etching helps you meet these standards. You can add codes, dates, and safety marks to every package.

- You mark medicine bottles with approval numbers.

- You add safety warnings to pill packs.

- You use laser etching for tamper-evident seals.

Laser etching gives you marks that cannot be changed or removed. You show customers and inspectors that your products are safe.

| Compliance Mark | Example Use | Why It Matters |

|---|---|---|

| Approval Code | “FDA 12345” on label | Shows legal approval |

| Warning Symbol | ⚠️ on pill pack | Alerts for safety |

| Seal Mark | “Sealed” on box | Prevents tampering |

Traceability

Traceability means you can follow a product from start to finish. Laser etching lets you add serial numbers, batch codes, and barcodes to every item.

- You mark each pill bottle with a unique code.

- You add batch numbers to vaccine packs.

- You use barcodes to track shipments.

Laser etching helps you find and fix problems fast. You can recall products quickly if needed. You keep patients safe and build trust.

Tip: Use laser etching for traceability to meet industry rules and protect your customers.

Art and Design

Laser etching opens new doors for artists and designers. You can create detailed artwork, test ideas, and decorate many surfaces. This process gives you freedom to try new things.

Artwork

You can use laser etching to make art on wood, glass, metal, and more. The laser draws lines, shapes, and patterns with high precision.

- You create portraits on wooden plaques.

- You etch landscapes on glass panels.

- You design jewelry with custom marks.

Laser etching lets you make art that lasts. You can sell unique pieces or give special gifts.

Prototyping

Prototyping means you test ideas before making the final product. Laser etching helps you make quick samples and models.

- You etch logos on sample products.

- You mark parts for design tests.

- You create mock-ups for clients.

Laser etching saves you time and money. You can change designs fast and see results right away.

| Prototyping Use | Material | Benefit |

|---|---|---|

| Logo Sample | Plastic | Fast feedback |

| Model Part | Metal | Accurate testing |

| Mock-up | Wood | Easy changes |

Decorative

You can use laser etching to add decoration to many items. The laser makes patterns, borders, and textures that stand out.

- You decorate phone cases with custom designs.

- You add patterns to furniture and home goods.

- You make holiday ornaments with names and dates.

Laser etching gives you endless options for decoration. You can make products look special and attract more customers.

Note: Laser etching in art and design helps you create, test, and decorate with ease. You get high-quality results every time.

Considerations

Cost

When you want to use laser etching, you should think about how much it costs. The price can be different for many reasons. If you want the newest machines, you might pay more. New machines can do a better job, but they are often more expensive because they are more advanced. What kind of work you do also matters. Some jobs need special features or custom designs, and this can make the price go up.

You should pay attention to these main things that change the cost:

- Technological development: New machines cost more but can give better results.

- Industry application requirements: Some jobs need special settings or custom marks.

- Market competition: Different brands have different prices and features.

- Supply chain dynamics: The price of materials and how easy they are to get can change what you pay.

If you want to spend less, look at different machines and sellers. Pick a system that does what you need, but do not pay for things you will not use.

Tip: Always make sure the machine works with your material and project before you buy it. This helps you not spend too much.

Speed

Speed matters when you need to finish work fast. Laser etching is much quicker than old marking ways. You can mark lots of items in a short time. This helps you keep up with big orders and tight schedules.

Here are some reasons why laser etching is faster:

- Laser engraving is much faster than old engraving. You can finish big batches quickly.

- Laser etching gives quick and good results for lots of work.

- You get faster work and better efficiency than with older marking ways.

You also get marks that are neat and correct. This makes laser etching good for many jobs. If you need to mark thousands of parts, laser engraving can help you stay on track.

Note: Fast marking helps you save time and money. You can finish more work without waiting.

Durability

You want your marks to last, even in hard places. Laser etching gives you strong marks that stay for a long time. These marks stay clear even if they get hot, wet, or scratched.

The table below shows how laser-etched marks do in tough places:

| Durability Aspect | Description |

|---|---|

| Unmatched durability | Marks can handle very hot, cold, or rough treatment. |

| Permanent identification | Marks do not wear away in hard conditions. |

| Extreme durability | Engraved marks do not fade or rub off easily. |

| Corrosion resistance | Marks last through cleaning and harsh places. |

| Permanent markings | You can always track the product with these marks. |

Laser engraving helps you meet rules for strong marks. You can use it for parts that need to last a long time. The marks stay easy to read and do not fade, even after many years.

Tip: Pick laser etching if you need marks that last in tough places and keep your products safe.

Environment

When you pick laser etching, think about how it affects nature. Laser etching is often cleaner than old ways of marking things. But you still need to watch out for some things.

Laser etching does not use ink or harsh chemicals. You do not have to worry about spills or waste from dyes. This keeps your work area safer and helps keep air and water clean. Modern laser machines use less energy. Fiber lasers, for example, turn more power into light. This means you do not waste as much electricity.

But laser etching can still make smoke, dust, or fumes. Some things, like plastics or composites, let out gases when heated. You need good airflow to keep the air safe. Use air filters or fans to get rid of bad particles. If you do not know what a material is, test it first. This helps you see what kind of fumes it makes.

Here is a table that shows how laser etching is different from other marking ways:

| Method | Chemical Use | Waste Produced | Air Quality Impact | Energy Use |

|---|---|---|---|---|

| Laser Etching | None | Low | Medium | Low |

| Ink Printing | High | High | High | Medium |

| Chemical Etching | High | High | High | High |

| Mechanical Marking | None | Medium | Low | Medium |

You can make laser etching better for the earth by doing these things:

- Choose machines that save energy.

- Use materials that do not make toxic fumes.

- Put in air filters and keep your area tidy.

- Recycle scraps and dust if you can.

- Teach your team how to handle materials safely.

Tip: Always check the safety info for each material before you start. Some plastics and composites can make bad gases when heated.

You help the earth when you use laser etching instead of chemical marking. You make less waste and do not use harmful stuff. You also save energy with new machines. If you want to be even greener, try to recycle and reuse what you can.

Laser etching lets you mark things with less harm to nature. You can keep your team and your town safe by making smart choices. If you care about the planet, laser etching is a good choice.

Laser etching has many good points for making things and design. Here are some of the main benefits:

- Precision lets you make marks that are very exact.

- Efficiency means you waste less and save money.

- Speed helps you finish big jobs fast.

- Versatility lets you use many kinds of materials.

- Adaptability means you get good results on different tasks.

If you want to see if laser etching is right for you, try these steps:

- Choose what kind of mark you want to make.

- Make sure the laser works with your material.

- Think about where you will do the work.

- Decide if you need to mark things quickly.

- Pick a machine that can handle lots of materials.

Look into laser etching to make your work better and stay ahead in your field.

FAQ

You can use metals, plastics, ceramics, glass, wood, leather, and composites. Every material acts in its own way. Always test your material before you begin a project.

You stay safe by wearing goggles and using good airflow. Keep your workspace clean at all times. Always follow safety rules and check your machine before you start.

Laser etching only changes the very top layer of your material. The mark is shallow but will not go away. If you want deeper marks, you should use laser engraving.

You can make very tiny details with laser etching. Fiber and UV lasers are best for small text, logos, or patterns. You get sharp and clear results every time.

Laser-etched marks last for many years. They do not fade from heat, water, or scratches. You can trust these marks to stay easy to read in tough places.

You can etch on curved surfaces, but you need special tools. Some machines use rotary parts to help you mark bottles, rings, or tubes.

You see laser etching in factories, car making, electronics, medical, airplanes, jewelry, packaging, and art. Each industry uses it for marking, labeling, or decoration.

A You should learn how to use your machine before you start. Read the manual, watch training videos, and practice on test pieces. Good training helps you avoid mistakes.